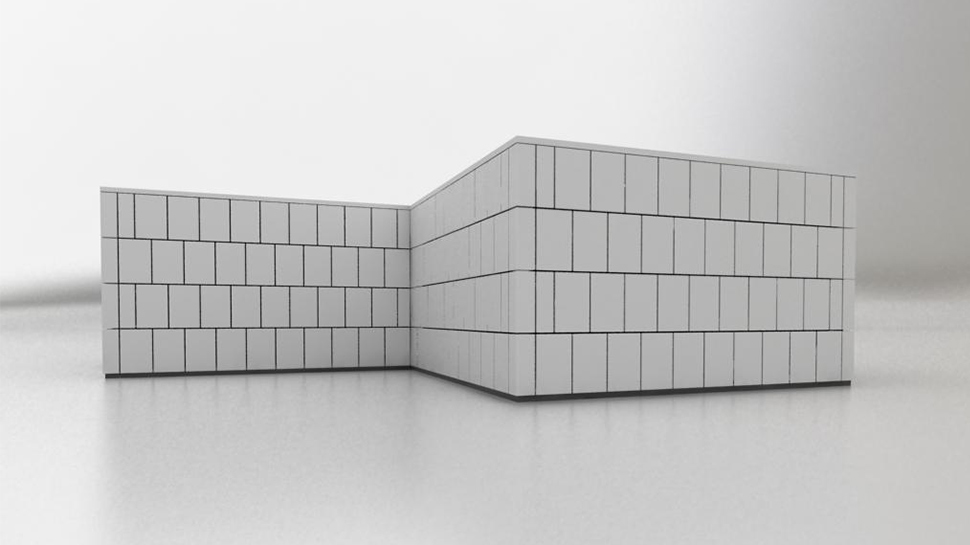

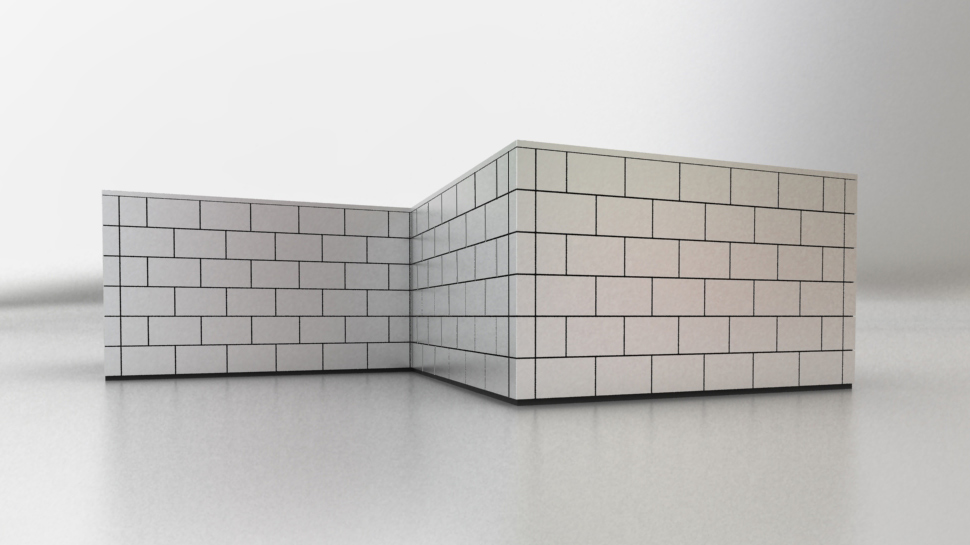

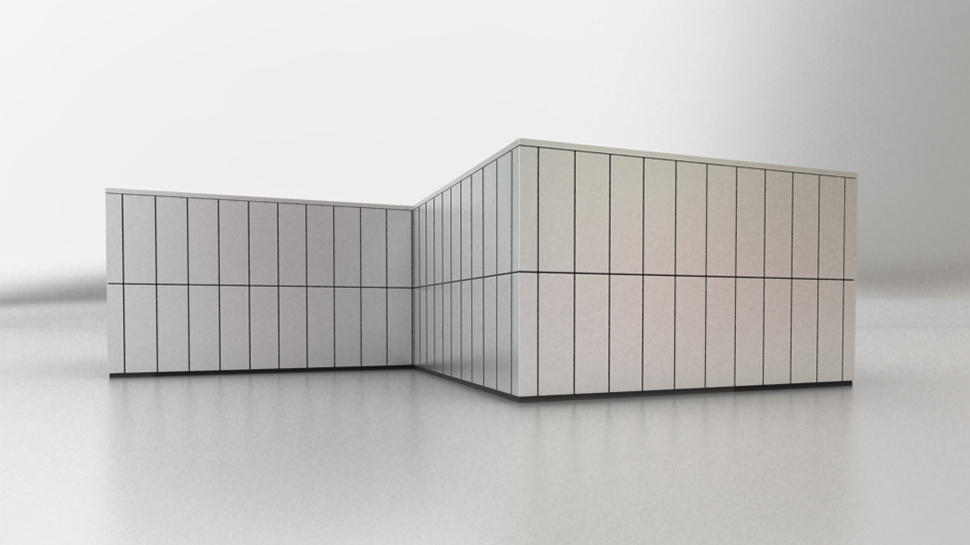

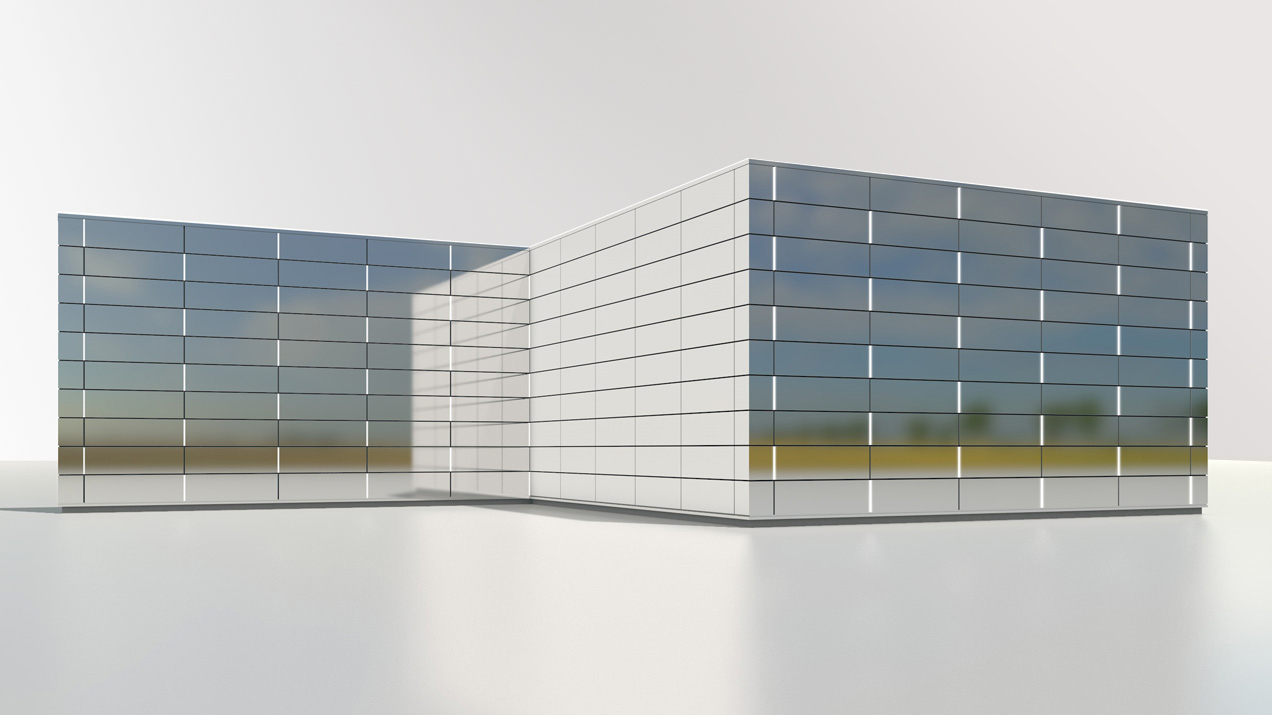

UNLIMITED DESIGN POSSIBILITIES

Qbiss Screen is distinguished by its outstanding aesthetics, which are engineered for the widest architectural applications. From the vast joint permutations and combinations to the different installation variations, colours and material finishes.

Without doubt, Qbiss Screen is one of the smoothest and flattest metal rainscreenin its class. The façade element itself is distinguished by a unique and patented rounded corner, which eliminates the need for any rivets, cuts or welding, which would be visible on a traditional metal solution Qbiss Screen has no equal. Trimo is the leading rainscreen manufacturer.

DESIGN ADVANTAGES

- Unique rounded corner of the element

- No cuts, folds or welds

- Completely flat surfaces

- Available as flat and standard prefabricated corner elements

- Wide range of architectural details available

- Various joint options

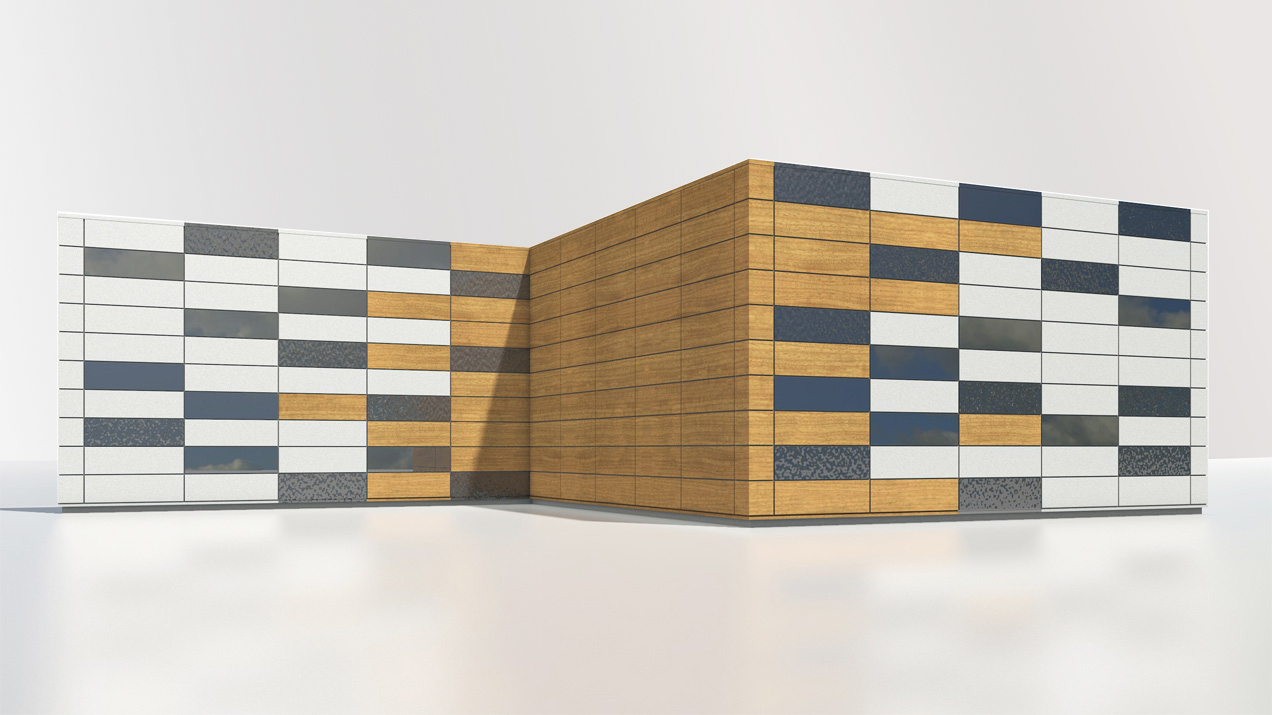

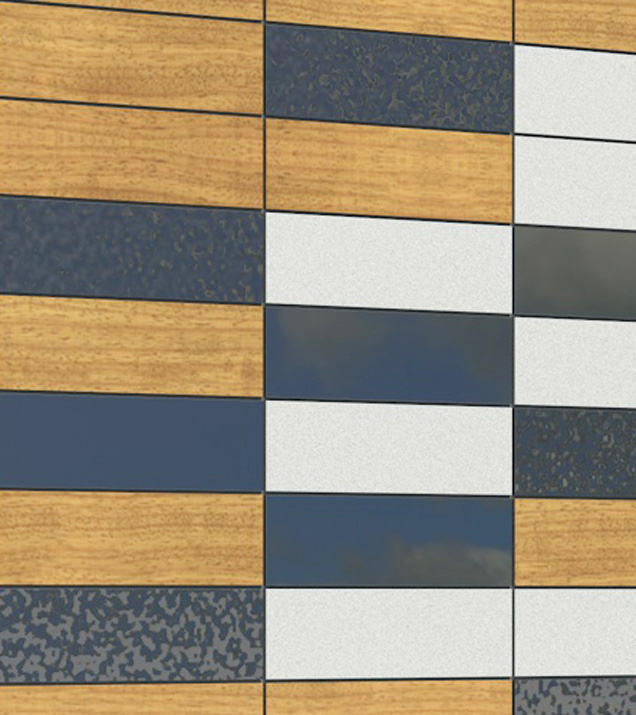

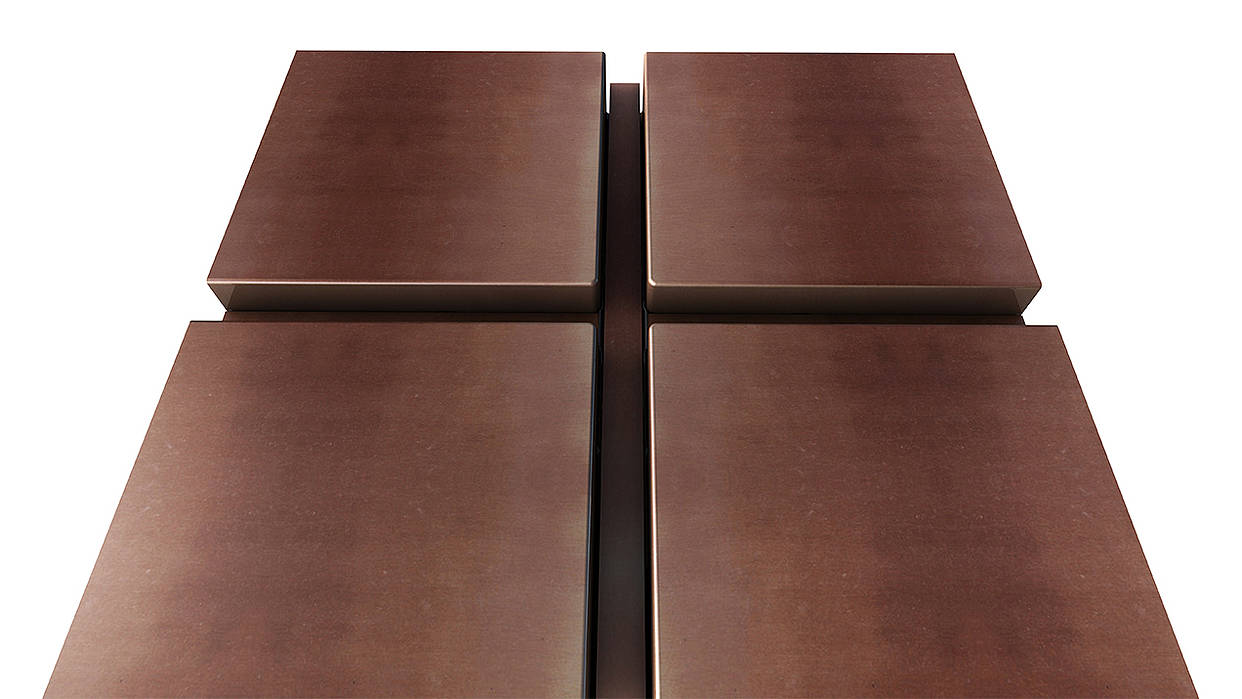

- Range of material finishes (steel and stainless steel material and in carbon, wooden, copper or other appearance)

- Wide range of colours

- Versatile installation options

- Integrated LED lights in the joints

UNIQUE FLATNESS, LARGER SIZES

Clean and smooth rainscreen designs are possible with Qbiss Screen, which excels in its extreme flatness at any element size, with lengths from 550 mm up to 6,500 mm and widths from 600 mm up to 1200 mm.

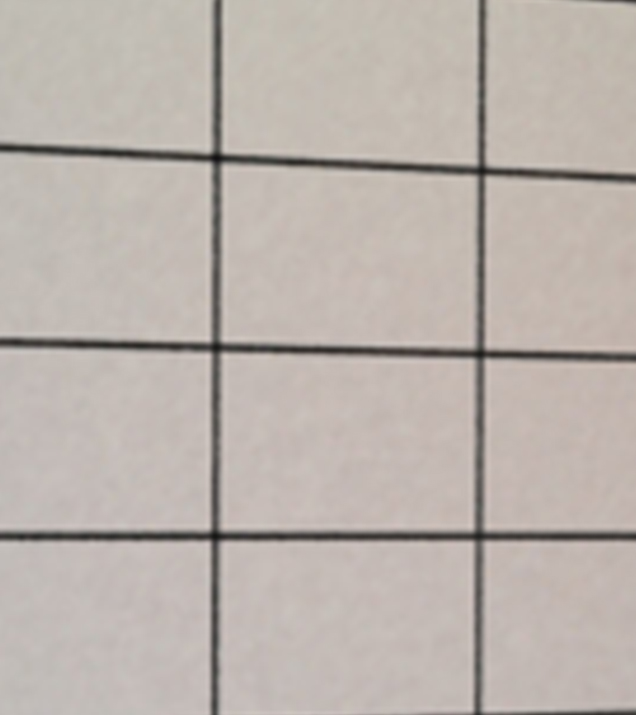

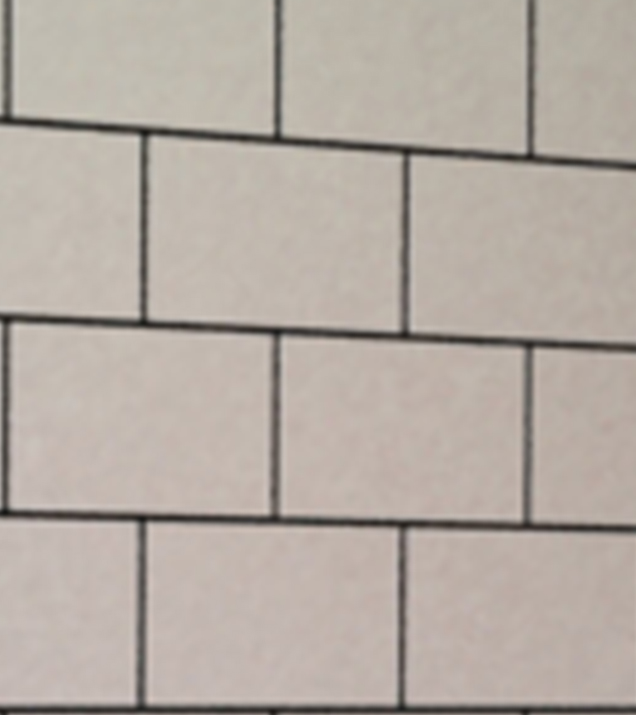

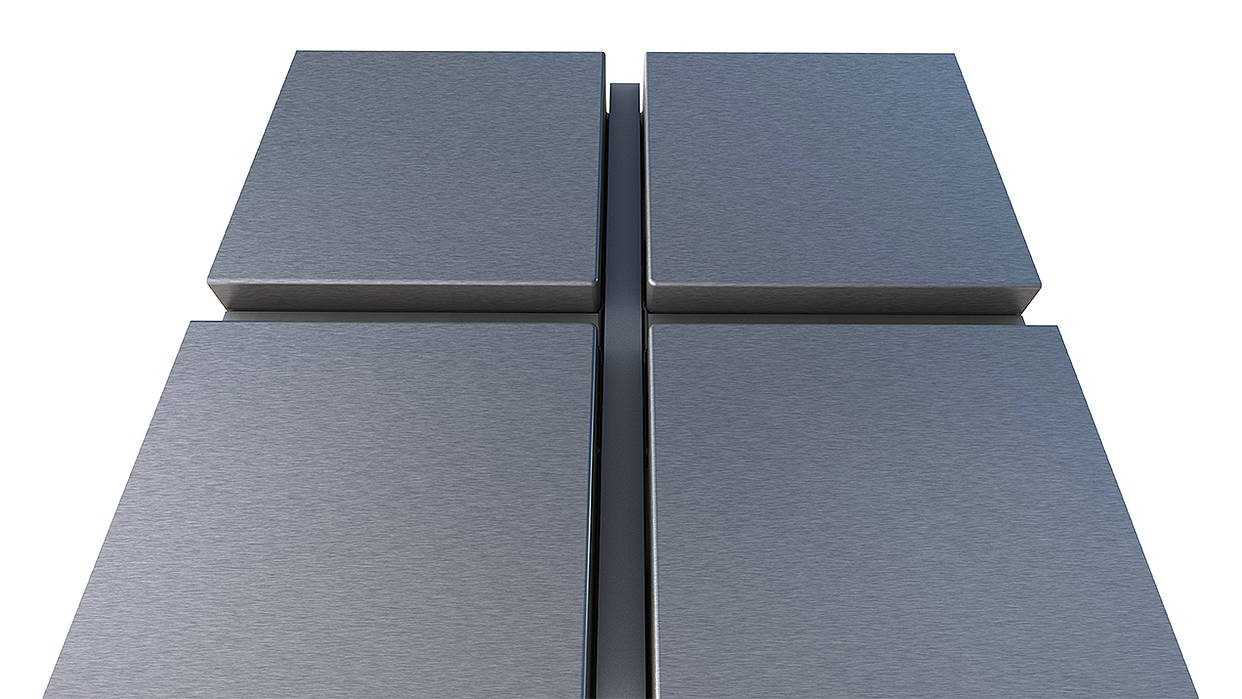

JOINT OPTIONS

Qbiss Screen system allows the combination of various permutations of recessed and flush joints.

INSTALLATION OPTIONS

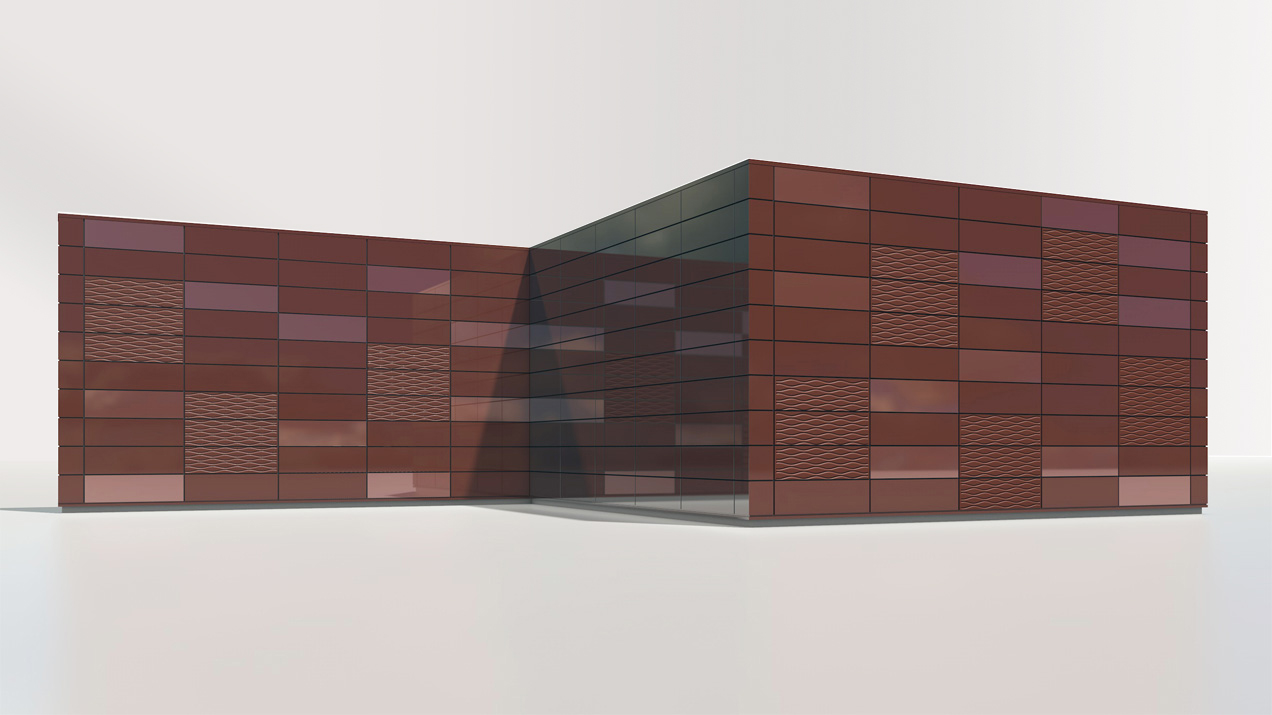

COLOURS

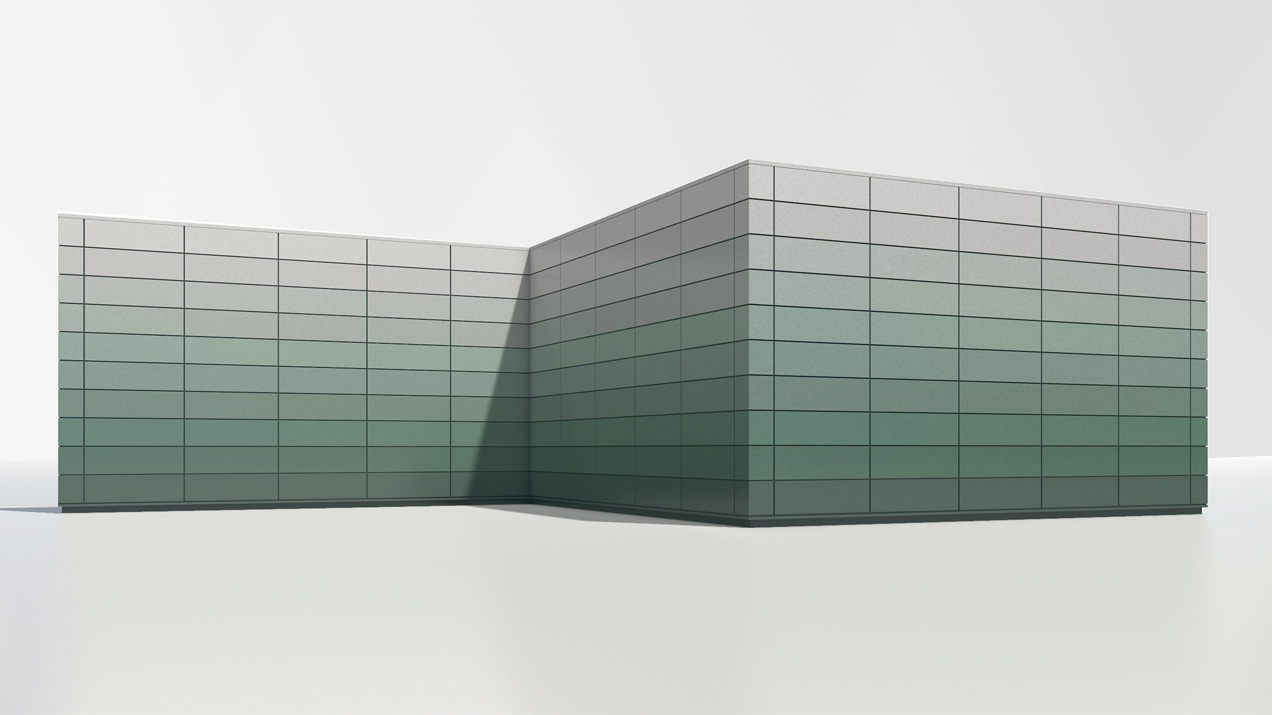

Qbiss Screen offers endless rainscreen design possibilities with its wide range of colours, material finishes (steel, stainless steel) and appearances (carbon, wooden, copper or other).

Colour options for the rainscreen cladding are:

- One colour for the whole building

- Different colours of elements organised in a random pattern or in large colour surfaces

- Different colours of shadow line

*Trimo is the leading rainscreen cladding manufacturer. Other colours are available upon request.